Technology

Bio-methanol from waste biogas using Innovative catalyst technology

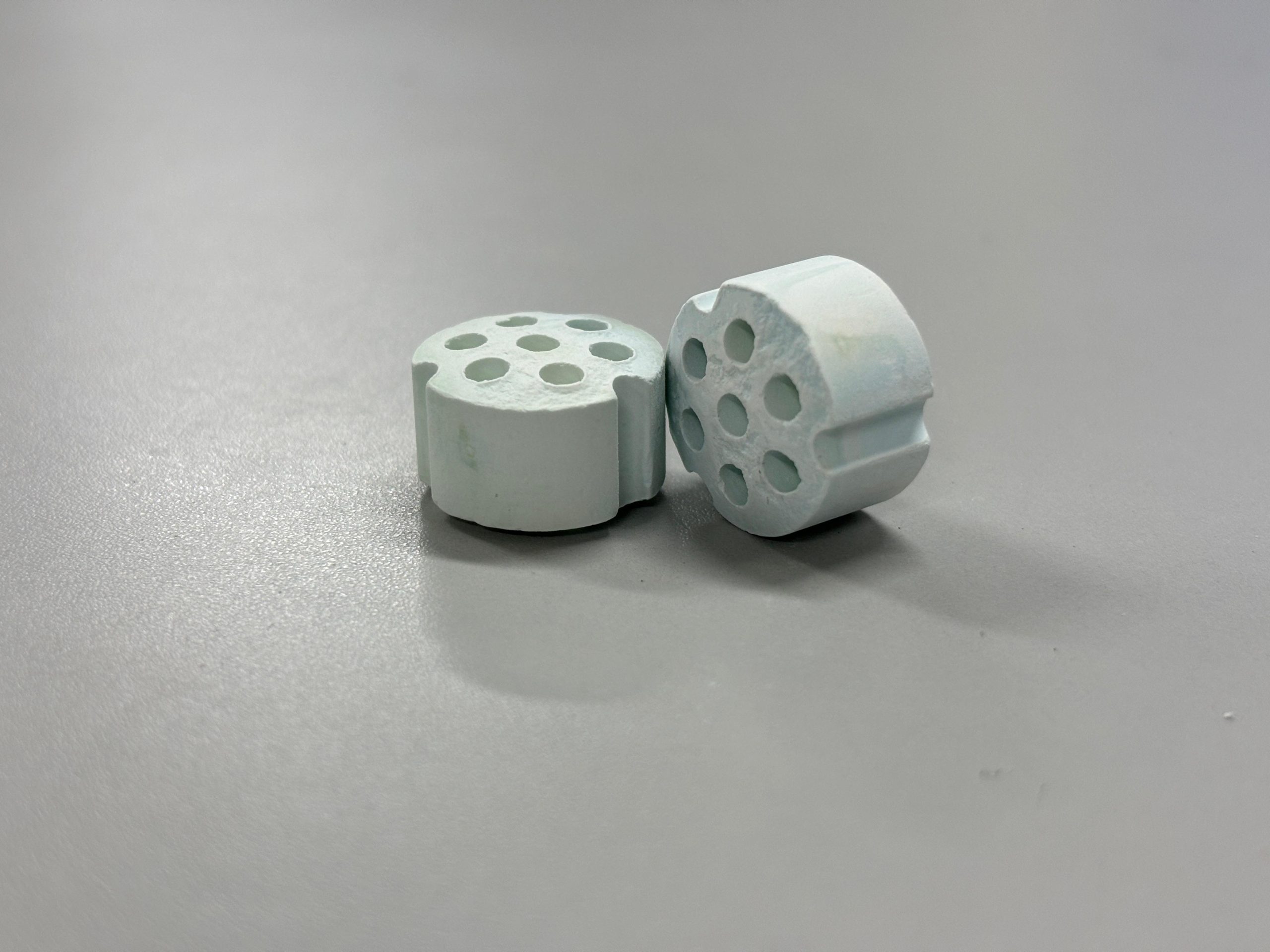

CRecTech has developed a breakthrough catalyst, CRecREFTM, that turns raw biogas, made up of methane and carbon dioxide, directly into renewable bio-methanol in just two steps instead of the conventional four step process. Our catalyst not only prevents carbon build-up but also puts CO₂ to work as part of the reaction, producing the perfect gas mixture needed to make methanol.

This means we skip expensive cleaning and conditioning steps, cutting production costs by up to 50%. The result is a highly sustainable way to turn biomass wastes into affordable green fuel for the shipping industry and beyond.

Steam Methane Reforming Problems

Steam Methane Reforming (SMR) faces challenges like high CO₂ emissions, catalyst degradation, and energy inefficiency.

Two Processes

CRecTech is pioneering low-carbon solutions through two key innovations — reducing fuel use, water consumption, and CO₂ emissions.

Conventional SMR

4 steps · High cost · High emissions

- 1Biogas cleaning

- 2CO₂ removal

- 3Steam reforming

- 4Methanol synthesis

CRecTech · CRecREF™ Process

2 steps · 50% lower cost · Carbon neutral

- 1Steam biogas reforming

- 2Methanol Synthesis

Renewable Bio-Methanol

Modular Solutions Converting Waste to Renewable Bio-Methanol

Modular & Rapid Deployment

Modular units with a small land footprint, enabling fast setup near feedstock sources.

Plug and Play Integration

Connects seamlessly to existing biogas, heat, and storage infrastructure with minimal disruption.

Cost Efficient CAPEX

Standardized modular design lowers upfront investment, making renewable bio-methanol production economical.

Ready to explore deployment for your operations?

Book a Meeting →Breakthrough catalytic technology for

renewable bio-methanol production